INTRODUCTION

The LEGO Technic's Flagship model of the year 2015, the Mercedes-Benz Arocs 3245 has alot of Technic fans going crazy over it. Here are some of the reasons why :-* Designed by Markus Kossmann, a designer of many other LEGO Technic's Flagship Model such as 8421 - Mobile Crane, 8275 - Motorized Bulldozer, 8110 - Mercedes-Benz-Unimog-U-400 and 42009 - Mobile Crane MK II

* At 2793 pieces, the larges LEGO Technic set to date. Beating the previous largest set (42009 - Mobile Crane MK II) by 187 pieces

* A Successor to the 8110 - Mercedes-Benz-Unimog-U-400 (Being also smaller by 748 Pieces)

I have actually builded this model a day ago but have found some errors on my build. Thus, i have decided to unbrick the whole set and rebuild it. Thus the photos that are being showed below are actually the second attempt that i'm doing this. Also, forgive me if the photos appear blur or not up to standards as i do not have a proper studio to shoot them. As you can see, i'm actually building this model in my bedroom

BOX CONTENTS

As with most LEGO Technic sets, the majority of the parts actually are made up of 2780 - Connector Peg. W. Friction. A whole whopping 451 pieces of them (That's about 16 % of this set)

Next are the new Pneumatics V2 elements of this set. They are made up of :-

* 1 19482 - Pneumatic Pump 1 X 6 No.1

* 1 19475 - Pneumatic Cylinder 1 X 5 No.1

* 1 19476 - Pneumatic Cylinder 1 X 11 No.1

* 2 19478 - Pneumatic Cylinder 2 X 11 No.1

* 4 47223 - Welded Two-Way Valve

As you can see, they are fairly similar to previous pneumatic elements but at closer inspection of the pumps, cylinders and valves, you will notice that their tube connectors are more conical in shape. This makes connecting the pneumatic tubes to these elements much easier.

The 99021 - Bush W/Connecting Piece and 4697 - T-Piece however, are still of the old design and has not been redesigned with the conical connectors. This is a puzzling move by LEGO

The star of this set ! 1 of the only 2 printed elements of this set, the 21100 - Shield No. "6" is the printed shield element of the Mercedes Benz's logo itself. Only 1 is given. thus there are no spares.

You might also have noticed the large single instruction manual of the first photo. Yes, it's large and if you turn to the last page of the manual, it's page 471 !

If you still want a better perspective of how thick this manual is, here's a comparision of it's thickness to the set's tyre !

The last honorable mention of the set items is the decals. Notice that the number plate of the set reads K055M4NN, refering to Markus Kossmann as the designer of this set. As a note, i will not apply decals to my set as i always liked to dismantle my sets and rebuild them from time to time as a cleaning process.

THE BUILD

Finally, on with the build ! As mentioned, there are 6 phases to the build and i shall try to describe them as detailed as possible

PHASE 1 - Front Axle, Battery Housing, Engines

The first 14 steps of the instructions manual, builds the housing for the engines

which then you build the v6 inline engine. There's nothing new about the engine build from other LEGO technic builds. the same build making it quite a routine quick build

The completed engine build and now it's connected back to the original main build

The Motor element goes just right behind this engine. This means i have to wire manage the engine cord from now on.

A few steps later, and the motor housing is complete.

The next sub build would involve 1 of the 2 front axle and it's suspensions

along with the second front axle and it's suspensions. It looks fairly similar to the first axle but has a small difference and thus the building instructions are detailed twice in the manual instead of an X2 build

After the axles, the build is followed by the battery box housing. The battery box will slide in between the 32063 - Technic 6M Half Beam and secured to the model by the two lower 32054 - 2M Fric. Snap W/Cross Hole connector pins. This means if your model runs out of battery, you could just pull out the two pins and take out the battery box easily.

Then you build these lights which connects to the battery housing and the axle below with the gears.

This is done so that if you twist this lights, the front axle would turn along with it. Nice design but kinda weird as turning lights = turning axles is a weird concept.

The exhaust ports are also detailed in this model with this build which consists of a number of 2M Cross Axle W. Grooves, Angle Elements and Brick 16 W. Cross elements

Finally, the first pneumatic tubes is added to the model. With that, the build of phase 1 is completed at page 118 and 68 steps for phase 1

PHASE 2 - Gear Racks and Out Riggers

And straight off, we build the outrigger arm. As mentioned earlier, the outrigger arm just uses 2 elements. This make the build quick but boring. if you look at the photo above, a 32062 - 2M Cross Axle W.Groove is added to the gear rack to prevent it from falling out of the housing.

The outrigger's leg are then build. As a note, the Outriggers will be extended by the power functions using the motor that we have added to the set in Phase 1 but the legs are extended manually using the 32270 - Double Conical Wheel Z12 1M. Another let down compared to the 42009 Mobile Crane where the outrigger legs are extendable via power functions.

A mirror is build for the other side and connected together to form the complete outrigger extender

Then, we move to building the first gear rack for the set. These functions to extend or retract the outriggers using the 2 32270 - Double Conical Wheel Z12 1M.

which seats above the outriggers that we just build like so.

Directly after, the pneumatic pumps are added to the set

Another piece to worth mentioning are these new gears 18946 - Gear Wheel Z16 W.4,85. Unlike the old ones, we dun have to take care of if the gear is inserted upside down as it's reversible on both sides

That element is used alot here on the second gear racks which will go again directly above the outrigger extended gear racks

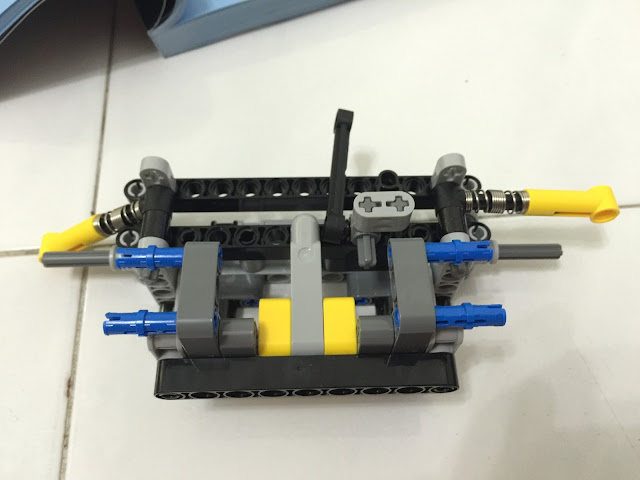

And here's a last look at the complete build of phase 2 before it's connected back to phase 1's build

Phase 2 build complete at page 156 with 70 steps for phase 2

PHASE 3 - Rear of Truck, Tipping Bed and Rear Axle

The first noticable build is these 4 45590 Damper 2M used in the build. I'm not quite sure why these dampers are used instead of 2M Beams

And we build the base of the rear end of the truck

The tippig mechanism of the truck is then build using a 61927 - Linear Actuator 10-15 M instead of a pneumatic cylinder.

The build is connected to the base we build earlier like so

Rear suspensions are added to the base

The rear axles are then build in 3 parts. the photo above being part 1

The middle part of the axle to connect both the axles

And the whole build of the rear axle

The whole rear axle is connected to the tipping bed build earlier.

The build is then connected back to Phase 1 and Phase 2 of the build..

And then finally tyres are added to the build. All 12 of them. And that ends the build of Phase 3 at page 254 with 92 steps

PHASE 4 - Pneumatic Crane

In Phase 4 we go on to build the highly talked about pneumatic crane.

i'm showing these 2 photos as i have found an error on the instruction manual. If you notice the page 255 ends with step no.2 but as you turn to page 256, the instruction starts at step 4. Also 2 6558 Connector Peg W. Friction 3M is magically added. I have emailed this mistake to LEGO and they have since replied me that they are correcting this problem and also the online building instructions has corrected this error as well.

The base of the crane is then build. Notice the color coded 60484 T-Beam 3x3 W/Hole 4.8 and also 32526 Technic Ang. Beam 3x5 90 Deg. Beams. They are crucial for organizing the pneumatic tubes later on in the small space that is provided here

The first part of the crane support arm is coming up

And the first pneumatic cylinders are to be added to the crane support arm that i just build

Those pneumatic tubes are to be organized through the yellow T-Beam that i mentioned earlier

The second T-Beam are to go through the Gray T-Beam

The 3rd Set of pneumatic tubes goes through the Blue L-Beam

and finally the last set of tubes goes through the Black L-Beam. Do this carefully as you will run out of space really quickly if it's not organized properly (as i did at my first attempt)

And this is the build of the base

And here's a look at the whole tubing on the base of the crane from underneath

The second section of the crane arm that is to be connected to the base using a Cross Axle 3M.

The third part of the crane arm. Notice that the outrigger housing and gear racks are used here again for the arm extension

And finally, the bucket clam shell build.

And here it is, the complete pneumatic crane build

This crane is then added to the rest of the build which looks like this, affectively ending Phase 4 of the set at page 328 with 97 steps

PHASE 5 - Cabin

The cabin's radiator grill building technique involves 61184 - 3M.Arch W.Knob And Shaft 3.2 and 41678 - Technic Cross Block/Fork 2x2 build in such a way to achieve the sleek grill look. the 3M.Arch W.Knob are then attached to Flat Tile 1 X 2 and Flat Tile 1 X 3 to complete the grills

The lowest grill is slanted in a small degree like the real Mercedes Benz Arocs. The build itself should be sufficient enough for the angled grill. However

the designer went a stop further and reinforce the slanted angle with more technic pieces to make sure that it stayed in place perfectly

The completed lower bumper build

After that, it's on to the 2 chairs of the cabin

Followed by more grilling with the same technique shown earlier

The complete radiator grill and also the Mercedes Benz logo added to the set.

This piece finishes the front of the truck

And the complete build of the cabin ! looks really detailed and worth the time to build it. That completes Phase 5 at page 427 and 102 steps

PHASE 6 - Tipping Bed

The tipping bed has no interesting build except for a square open box. Thus i shall not really cover the build.

COMPLETE MODEL COMPARISON

And here, the comparison of the 42043 to other flagship models. Unfortunately i do not have the Unimog and thus, could not compare the Arocs to it.

CONCLUSION

Cons

* The outriggers build has been simplified and thus becomes boring unlike the 42009 Mobile Crane

* The outriggers legs are not motorized like the 42009 Mobile Crane

* The ClamShell of the 42043 is not as usefull compared to the VOLVO L350F Wheel Loader's bucket

* The tipping bed is boring :P

Pros

* 10 hours of great build (well roughly, and also the tipping bed build was boring tho)

* The model looks great with the cabin's great detail build

* Have fun with the new pneumatic pumps cylinders and valves

Again, I do not have the Unimog and thus could not do an actual comparison to it but i would say that although of the downfalls compared to previous flagship models, this set is a blast to build and i would highly recommend getting it !